NEWS

STAY TUNED

NEWS

STAY TUNED

HOW IPC STANDARDS CONTROL AND OPTIMIZE THE PRODUCTION OF ELECTRONIC BOARDS

November 19, 2021

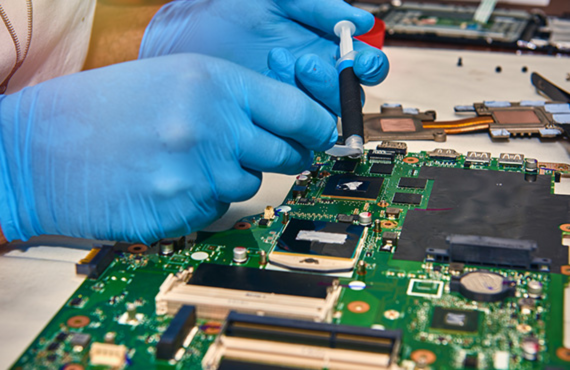

IPC standards ensure quality production by imposing specific standards and requirements throughout the manufacturing process of our electronic boards. These internationally recognized production standards make the production of your electronic components fluid and secure.

Benefits of IPC standards

The more functions a PCB contains, the more complex and expensive it becomes to produce. It is therefore essential to ensure a perfect and flawless design of the printed circuit board to ensure the smooth production of the finished product, especially when adding other components. IPC standards allow to control and ensure the quality and reliability of a printed circuit board, considerably reducing errors and thus allowing to optimize the production and assembly costs of a finished product.

Today, IPCs are common and internationally recognized standards, which simplify exchanges between EMS and customers.

What IPC standards are in place at AMW?

At AMW, we mainly work with the IPC A-610 “Acceptability of Electronic Assemblies” standard, which covers all requirements related to the production and performance of printed circuit boards. This standard is categorized into several classes, which are requirement levels defining criteria for the different production steps, from soldering, to plating, to surface coating, etc. We usually apply class 2 to all of our PCB production, but we are also trained in class 3 if required.

AMW also masters other IPCs on board design, for example to ensure proper spacing of components to ensure good soldering, or other IPCs to measure the sensitivity of components to moisture.

Training, monitoring and implementation of these standards within AMW

Internally, our CIT trainer, certified by the IPC organization, is able to issue IPC certificates by training all operators involved in the IPC A 610 manufacturing processes. Once trained, the controllers ensure that everything is done correctly and that the standards are respected throughout the process. Inspection method includes X-ray pictures on every lot produced for specific components based on design or risk analysis.