NEWS

STAY TUNED

NEWS

STAY TUNED

STAY IN TOUCH

If It’s making news in our industry, you’ll find it here.

Discover the latest industry, headlines, trends, and more. Count on the best engineering and manufacturing expert at AMW for the latest industry intel and the clear guidance you need to make smart and advised decisions.

Nov 19, 2025

OUR NEW ACHIEVE: ANSI/ESD S20.20-2021 CERTIFICATION

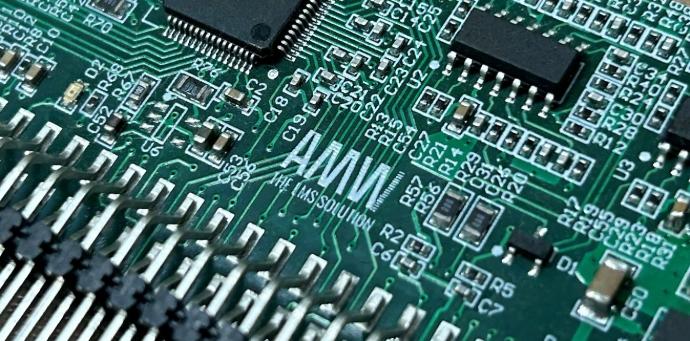

We have been officially certified for Electrostatic Discharge Control – ANSI/ESD S20.20-2021 by BSI. This certification reinforces our commitment to world-class operational standards and continuous improvement across our manufacturing processes. The certification covers the Manufacture of

PCB Assemblies and Power Converters, demonstrating our capability....

September 14, 2023

INTRODUCING: OUR NEW AMW R&D DEPARTMENT

In today’s fast-paced world, EMS companies are encountering numerous challenges to stay at the forefront of the industry and meet clients’ needs. As an international electronic player, AMW-EMS decided to diversify its activity over the past 20 years through an innovative industrial policy, great responsiveness, and an investment capacity thanks to our long-term relationships with our customers in various markets.

August 10, 2023

OUR NEW MACHINES SERIES: OUR SEMI-AUTOMATIC SMC-1SD TOROIDAL WINDING MACHINES FROM JOVIL

How do our SMC-1SD Toroidal Winding Machines work? Firstly, the supervisor sets the program of our Semi-Automatic SMC-1SD Toroidal Winding Machine to determine the number of windings wanted. For example, it can be 200 windings per layer with a total...

July 12, 2023

OUR NEW MACHINES SERIES: OUR NEW SEMI-AUTOMATIC PCBA CUTTING MACHINE (AUROTEK)

Our “Intelligence for excellence service...

June 22, 2023

OUR NEW MACHINES SERIES: MULTI SPINDLE WINDING MACHINE (NITOKU)

How does our Multi Spindle Winding...

April 27, 2023

IN SHORT: OUR PCBA LASER MARKING MACHINE FROM YOUNGPOOL TECHNOLOGY

The marking of our PCB has a crucial...

May 31, 2022

IN SHORT: AUTOMATIC FIRST ARTICLE INSPECTION FOR NEW PCBA PRODUCTION

For any new PCBA production order...

February 02, 2022

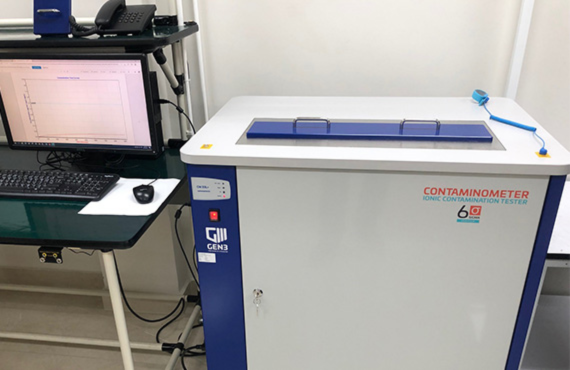

IN SHORT: BOARDS WASHING MACHINE & CONTAMINATION TESTER

Both machines have an important...

December 03, 2021

WHY IS IT PRIMORDIAL TO WORK WITH YOUR MANUFACTURER IN THE EARLY STAGES OF YOUR NPI?

November 19, 2021

HOW IPC STANDARDS CONTROL AND OPTIMIZE THE PRODUCTION OF ELECTRONIC BOARDS

October 20, 2021

ACQUISITION OF MYD10X : THE NEW AUTOMATED IN-LINE DISPENSING SYSTEM

AMW recently acquired the MYD10X...

July 28, 2021

WOMEN IN THE MAGNETIC INDUSTRY: MEET THE WOMEN FROM THE AMW TEAM

Women employees at AMW share...

June 04, 2021

MANAGING SUPPLY CHAIN SHORTAGES: WHAT TO DO

Supply chain shortages within world allocations is a recurrent situation...

May 28, 2021

HOW AMW MEETS YOUR NEEDS: TEAM TRAINING AND TURNOVER MANAGEMENT

At AMW, we are committed to...

April 16, 2021

ELECTRONIC CARD FOR ELECTRIC CARS: THE E4V X AMW PARTNERSHIP

The EMS partnership between E4V and AMW celebrates its two years in 2021...

March 24, 2021

AMW DEVELOPS VIRTUAL AND REAL TIME VISITS OF ITS FACTORY IN THAILAND

At AMW, meeting our customers’...

March 24, 2021

THE 10 RULES FOR A SUCCESSFUL PROJECT WITH AN EMS

After several months of searching for an EMS partner, you are ready to...

December 17, 2020

COVID: SAFETY ABOVE ALL IN OUR FACTORY

With the current health crisis, AMW must be reactive and agile to effectively protect our...

December 17, 2020

IN SHORT: A NEW INNOVATION SYSTEM AT THE SERVICE OF PRODUCT QUALITY

AMW is equipped with the latest version of Keyence optical measurement, IM-7030...

December 10, 2020

THE ADVANTAGES OF CENTRALIZING THE PRODUCTION OF ELECTRONIC BOARDS AND MAGNETIC COMPONENTS

October 29, 2020

GET ACQUAINTED WITH OUR TEAMS : AMW SUPPLY CHAIN STRATEGY

How does AMW’s relationship with suppliers work? What are the goals...

April 15, 2020

COVID-19 UPDATE

At AMW, our priority remains on the safety of our employees, suppliers and customers...

16 March 2020

AMW-EMS – Grand Opening

Hervé Mouly (CEO and President of AMW) and Jacques Lapouge (French ambassador in Thailand)...